Production facilities with Siemens S7 controllers generate valuable data. But how do you make this data accessible for modern monitoring systems, dashboards, and analytics? The S7 Connector bridges this gap: A middleware solution that connects S7 protocols with MQTT, SparkplugB, and the Unified Namespace (UNS).

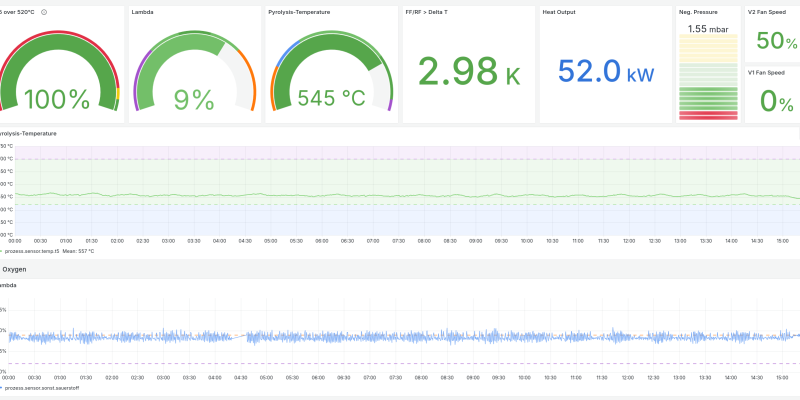

Pyrolysis boilers burn biomass highly efficiently – when they run optimally. However, without continuous monitoring, inefficiencies remain invisible: Too low combustion temperatures lead to energy losses, suboptimal oxygen supply results in incomplete combustion. This monitoring system captures over 300 data points per minute from Siemens S7 controllers and transmits them via MQTT and SparkplugB into a Unified Namespace. InfluxDB stores the time-series data, while Grafana dashboards provide real-time visualization and alerting. The result: Transparent operations management, optimized combustion, and centralized administration of multiple facilities across locations.

Technologies Used:

- Siemens S7 PLC

- MQTT & SparkplugB

- InfluxDB & Grafana

- Unified Namespace Architecture

- NodeRED

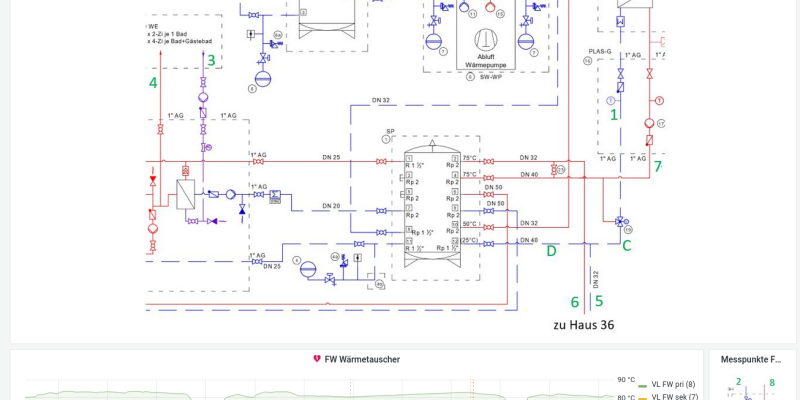

Together with the company 4E Engineers, a FOSS-architecture was designed and set up to allow for the comprehensive monitoring of any components of a building's technical equipment. Highly flexible edge node gateways collect data from a wide range of protocols, which are then made available for further analysis.

Technologies used:

- Docker

- Grafana

- InfluxDB

- NodeRED

- Flux

- Modbus

- 1-Wire

- WMBus

With OMIO I provide a service for secure, fast and easy management of your real-time data. Open source tools are orchestrated for data acquisition, storage and analysis to provide a basis for further analysis tools and algorithms. In addition, an interface for the connection of water monitoring winches has been developed.

Technologies used:

- MQTT

- NodeRED

- Telegraf

- InfluxDB

- Grafana

- Python

- GRAV CMS

- Docker Container